import Fogging Testing|fogging testing systems : fabrication Applied Technical Services performs DIN 75201 standard testing for clients looking to determine the fogging characteristics of specific interior materials in motor vehicles. Assista aos GIFs Sentando No Pau Mais Relevantes gratuitamente aqui no Pornhub.com. Lésbicas sexy, desenhos e animações pornô engraçadas. . gostosa gozando no consolo gozando no consolo cavalgando no consolo brasileira consolo rebolando no consolo cavalgando no dildo punheta guiada brazzers sentando na cara .

{plog:ftitle_list}

WEB5 de jan. de 2024 · A criadora de conteúdo conta com uma torcida de peso para o BBB 24. Ela afirma que nomes como Gabriel Medina, Lucca Picon, Juliano Floss, Vivi Wanderley, Clara Garcia e João Guilherme vão .

how to do fog test

compression test stress strain curve

Fogging tests measure the tendency for plastic or elastomeric materials to volatize substances which can condense and collect on other surfaces when in use.The Horizon Fogging Test System fulfills the DIN, ISO, and SAE standards for fog testing. Available with a choice of controllers, a range of features and a robust pump providing temperature accuracy of ±0.5°C throughout the entire .Fog testing is a method to recreate automotive interior out-gassing in a timely, measurable and repeatable way, utilizing various standards including DIN, ISO and SAE. The purpose of this .Applied Technical Services performs DIN 75201 standard testing for clients looking to determine the fogging characteristics of specific interior materials in motor vehicles.

Fogging test systems are used for determining the fogging value, or the moisture content condensed on, a variety of surfaces in a controlled environment. These products are commonly used to test windscreen glass, camera lenses, .

ARDL offers fog testing to measure the performance of polymeric materials when exposed to controlled environments designed to mimic real world applications. Performance criteria .For example, the ISO 6452:2007 standard makes it possible to determine the fogging characteristics of plastic- or rubber-coated textiles used as trim materials in the vehicle interior. The raw materials constituting these materials can also .Fogging test is to simulate the environment inside the vehicle under high temperature to check whether the material will produce the volatile substances and make the glass fogging. In .The fogging test helps vehicle interior manufacturers identify and develop products that outgas SVOCs at a reduced rate. The fogging test procedure – outlined in DIN EN ISO 75201 – helps recreate auto interior outgassing in a .

Filling out the CDC Dog Import Form. This form should be completed by the person importing (bringing) the dog into the United States (the importer, owner, or shipper). If the person importing the dog has difficulty completing this form such as due to a disability, this form may be filled out by someone else acting on behalf of the importer.

The amount of fogging condensate is determined by weighing the aluminum foil disk before (m1) and after the test (m2) and subtracting the known mass of the same aluminum foil disk before fogging • mF = m2 – m1 • mF = the mass of the fog condensate collected during .The iFogSimToolkit (with its new release iFogSim2) for Modeling and Simulation of Resource Management Techniques in Internet of Things, Edge and Fog Computing Environments. In the new release Mobil. Prepare your source file to import. To import existing test cases to TestRail via CSV, you will first need to prepare your CSV import file. You may need to export your existing test cases to a CSV or Excel file from another test management system first, and then make some minor formatting changes to properly import your test cases into TestRail.

how to conduct fog testing

Import wearer details & export fit test records, eliminating the need to track manually. Convenience just a download away Qualitatively tests both reusable and disposable respirator wearers with Bitrex® or Saccharin. Two modes, One app The app has two modes – one for fit testers who need less step-by-step guidance and one for those who . >>> import textstat >>> test_data = ("Playing games has always been thought to be important to ""the development of well-balanced and creative children; ""however, what part, . Designed for Arabic, an adaption of Flesch and Fog Formula. Introduces a new factor called "Faseeh". Further reading in This academic paper. Gulpease Index (Italian)Das Horizon Fogging Test System erfüllt die DIN-, ISO- und SAE-Normen für Fogging-Tests. Erhältlich mit einer Reihe von Reglern und Funktionen sowie einer robusten Pumpe, die während des gesamten Bads eine Temperaturgenauigkeit von ±0.5 °C sowie konsistente, wiederholbare Ergebnisse gewährleistet. Salt fog testing, also referred to as salt spray testing, is an internationally recognized and standardized method employed to evaluate the susceptibility of various materials, coatings, and finished products to corrosion. This rigorous testing procedure aims to replicate extreme and corrosive conditions typically found in salt-infested .

At ATS, we perform VOC and FOG emissions testing for different kinds of volatile substances. We check for medium to high volatility substances (up to C25) in the VOC class, low volatility substances (in range C14 to C32) called FOG compounds, and other compounds such as formaldehyde. We provide several methods for emissions testing.

Watch this video to understand what fogging is. Fogging it's about a phenomenon related to the automotive sector that involves all the different components i. The salt fog test, also known as salt spray testing or salt corrosion testing, is a standardized procedure used to simulate and assess a coating's corrosion resistance. This test subjects the coated material to a controlled corrosive environment by exposing it to a dense saline fog. The aim is to replicate the effects of harsh environmental .

Fogging Tester Market Snapshot (2022-2032) [250 Pages Report] The global demand for fogging testers is slated to grow at a steady CAGR of 5.8% between 2022 and 2032, totaling nearly US$ 3 Billion by the end of 2032.Growth in the fogging tester market is attributed to the rapid expansion of automotive and aerospace industries and increasing need for enhancing .Fogging Test Chamber. Materials used in vehicles, such as plastics, fabrics, rubber or leathers, will evaporate under high temperatures and condense on the windshield and create a fog, which causes dangerous driving conditions. Fogging test is right to measure fogging characteristics of these automotive interiors as well as HID lamps.A guide to importing a car to the UK from the USA. What modifications are required, SVA and IVA tests, lights and preparation for MOT. . For new vehicles there was little testing to ensure that lights were correct etc during the first three years. However, nowadays the rules are strict and the Single Vehicle Approval (SVA) test, that my first . The ASTM B117 salt fog test is an essential tool for manufacturers to assess the durability and reliability of their products. By subjecting materials and coatings to the corrosive effects of salt fog, it helps identify weaknesses, potential failures, and areas for improvement.

Appropriate Control Strategies Eliminate the Need for Redundant Testing of Pharmaceutical Products Background To help ensure drug product quality and safety, national medicines regulatory authorities (NMRAs) in many countries have implemented, or are considering implementing, import testing requirements for pharmaceuticals, .9.5 Fogging time required for selected room: Following equation shall be used to calculate the fogging time Total fogging time (Min.) = Total quantity to be fogged / Flow Rate Room Name Fogging Solution Required Qty. Fogger Flow Rate Calculation Fogging Time Buffer Zone 610 ml 45-50 ml/min. 610 / 45 13.55 min ≈ 14 min.

Therefore, fogging test has become an important means for automotive manufacturers as well as auto’s inner decoration manufacturers to control product quality. At present, relevant domestic and international fogging test standards for auto’s inner decoration altogether involve three kinds of test methods: the reflectometric method, the . The ASTM salt spray test serves as a valuable tool in evaluating the corrosion resistance and durability of materials and coatings. By subjecting test specimens to controlled salt fog, The test provides accelerated corrosion conditions, enabling manufacturers to make informed decisions and improvements in product design, material selection, and coating . For what other purposes is a salt fog test conducted? Salt spray testing is as popular and as widely leveraged as it is for a variety of reasons. These benefits include: Affordability Involving a salt spray chamber, pressurized air and a salt solution paired with water, the simplicity of salt spray testing makes it budget-friendly. Salt spray . Fogging lens selection: Choose a fogging lens with appropriate power, usually +0.75 to +1.00 D, depending on the patient's age and accommodative ability. This lens should be placed in front of the non-tested eye. Adjusting fogging power: Increase the power of the fogging lens in small increments until the patient reports a noticeable blur.

The import of American VTEC, cone calorimeter ultra high cost performance more; Digital Elmendorf Tearing Tester Pendulum method test material tear strength, operating more simple, more accurate data . ES-X83231 Standard test method-For fogging of interior materials NES M0161 Interior materials fog test method D45 1727 TRIM MATERIALS AND .The fog test is commonly used in industries like e-coating or metal fabrication, where prolonged exposure to corrosive environments is expected. It provides a more realistic simulation and reveals potential weaknesses in protective coatings or finishings. The salt spray test might be more appropriate if you’re primarily concerned with surface .The corrosion salt fog test compares the protection of coupons cut from actual cylinder liners in a humid salt environment, and is intended to provide an indication of how well an oil formulation protects cylinder bores from rust. The Corrosion Salt Fog Test Methods run by Intertek are ASTM B-117 and NMMA.The Horizon Fogging Test System fulfills the DIN, ISO, and SAE standards for fog testing. Available with a choice of controllers, a range of features and a robust pump providing temperature accuracy of ±0.5°C throughout the entire bath ensuring consistent, repeatable results. High capacity heaters provide rapid heating to set point temperature

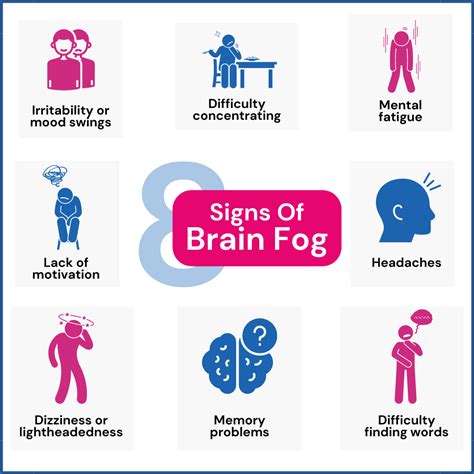

However, brain fog can affect one’s cognition and executive function. Brain fog is one of those issues many people face, especially those suffering from long-haul COVID, known as long-haulers. Here, we will discuss what brain fog is, the symptoms, how it is detected, associated health risks, and possible treatment options.ASTM B117 (Salt Fog Testing) is a standard test method developed by the American Society for Testing and Materials (ASTM) that determines the resistance of metallic materials to corrosion when exposed to a salt spray or salt fog environment. The test involves subjecting the material to a continuous mist of salt water for a specified period and then evaluating its corrosion .

webDe acordo com as estatísticas da Lotomania, os números mais sorteados foram 04, 05, 08, 11, 13, 15, 16, 20, 21, 23, 25, 27, 31, 33, 35, 37, 42, 43, 46, e 49. Os números menos .

import Fogging Testing|fogging testing systems